Products

Automatic Planers

AN-952

Inquire Now

Features

- Equipped with a digital position controller for accurate and convenient thickness adjustment.

- Straight cutterhead is standard. Helical cutterhead and quick change cutterhead are optional.

- Single infeed roller, twin outfeed rollers combined with twin table rollers exhibit powerful and stable feeding effect.

- Steel infeed and rubber outfeed rollers are standard.

- Rubber infeed and rubber outfeed rollers are optional.

- Varable feed speed is controlled by a frequency inverter.

- Powered table elevation provides effortless and fast thickness adjustment.

- The table is supported by 4 oversized columns thereby featuring maximum rigidity and stability.

- The table elevation is transmitted by 4 precision ball screws for accurate positioning and smooth movement ( Model AN-940 and AN-952 only )

- The massive cast iron table is precision ground.

- Automatic power-off function is activated when the top cover is opened.

- Anti-kickback fingers for operators’ safety.

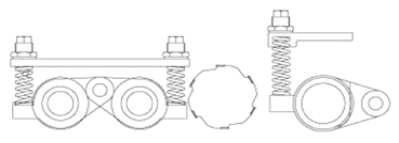

Special Lever Type Pressure Mechanism

Eliminating the conventional sliding block pressure device, the planer is designed with a new lever type pressure mechanism to increase pressure stability.

Digital Position Controller

Thickness of cut can be set by the digital position controller thereby providing high accuracy thickness control.

Hand Chrome Plated Table

( Model AN-940 and AN-952 only )

The table surface is hard chrome plated for maximum wear resistance and upgrading workpiece feeding effect.

The table surface is hard chrome plated for maximum wear resistance and upgrading workpiece feeding effect.

Precision Ball Screws

( Model AN-940 and AN-952 only )

The table elevation is transmitted through 4 oversized ball screws providing high positioning accuracy and extra smooth elevation motion.

The table elevation is transmitted through 4 oversized ball screws providing high positioning accuracy and extra smooth elevation motion.

Easy Adjustment of Table Rollers

The table rollers are easily adjusted by simply shifting a front-mounted adjustment lever. Both table rollers are adjusted in sync for convenience.

Specification

| MODEL | AN-952 | |

| Table area | 1320 x 1100 mm | |

| Max. planing width | 1320 mm | |

| Max. planing thickness | 300 mm | |

| Min. planing thickness | 3 mm | |

| Max. cutting depth | 9 mm | |

| Knives | Helical cutterhead | 6 Slots / 321 pcs |

| Knife sizes | Helical cutterhead | 15 x 15 x 2.0 mm |

| Cutterhead speed | 5000 rpm | |

| Cutterhead diameter | 125 mm | |

| Cutterhead motor | 25 HP | |

| Elevation motor | 1/2 HP | |

| Feed speed | 5-20 m/min | |

| Feed motor | 2 HP | |

| Net weight | 1800 kgs | |

| Gross weight | 2000 kgs | |

| Packing size (L x W x H) | 210x136x150 cm | |

| Machine size (L x W x H) | 186x118x135 cm | |

About Us

As time passes, business becomes more and more competitive. Success lies in the ability to produce quality goods at competitive prices. OAV Equipment & Tools Inc. is constantly working hard to improve and strengthen its corporate structure and meet new challenges.

Since its establishment in 1980, the top priority of OAV has been to provide the highest level of customer satisfaction possible. OAV continues this process today with state of the art facilities, a diversified product range, and the most rigorous quality control process in the industry. At the same time, there is more to OAV than high manufacturing standards. It is our dedicated staff that sets us apart, each of them bringing their passion and unique talents to the company.

At OAV, our focus is not only to improve product quality, but to also make strides in research and development, customer service, and sales. Our greatest strength is our dedication to offering the best possible service to meet the needs of customers all over the world. We spare no effort to ensure that each of our customers receives the highest possible level of customer satisfaction.

The people of OAV are devoted to the pursuit of excellence in all stages of the manufacturing process, as well as post-sale services. We strive to make our sales team easy to work with for every customer, regardless of language barriers or cultural differences. Our sales representatives regularly undergo training in order to meet any challenges that may present themselves while working with customers from all over the world. We pride ourselves in continuously improving all aspects of our business structure in order to keep pace with, and eventually set, international standards.

Business Type: Exporter

Main Products

Edge Banding Machine, Sliding Table Saw, Panel Saw, Circular Saw, Wood Band Saw, Dust Collector, Cut Off Saw, Fully Auto Finger Jointi,CNC Machine , Disc Sander, Disc and Belt Sander, Wide Belt Sander, Meat & Bone Saw, Combination Machine, Boring Machine

Contact Details

Related Products

Other buyers also viewed these products

PROFILE GRINDER

Inquire Now

Dust Collector

Inquire Now

CROSSFEED VENEER SPLICER

Inquire Now

Grinding Machine

Inquire Now

Economical, light duty model series

Inquire Now

Wide Belt Sandr

Inquire Now

MULTIPLE ROUND ROD MILLING MACHINE

Inquire Now

All Categories

All Categories