Products

Finger Jointing Machines(Finger Jointers)

F03

Inquire Now

Description

OAV finger jointing systems have been operated worldwide. The popularity of OAV finger jointing system is because the systems are designed with the purpose of finger jointing in mind. The OAV finger jointing systems are most user friendly and cost effective. This is achieved by OAV’s extensive experience and continued innovation.

Features

FC-05Finger Shaper (right End)It combines three functions – scoring, trimming, shaping in a unit on right end of the workpiece.

FC-05Finger Shaper (right End)It combines three functions – scoring, trimming, shaping in a unit on right end of the workpiece.

Production Rate- 2-4 cycles/min. (Long wood)

- 4-6 cycles/min. (Short wood)

- 2-4 cycles/min. (Long wood)

-

Left Shaping Mechanism

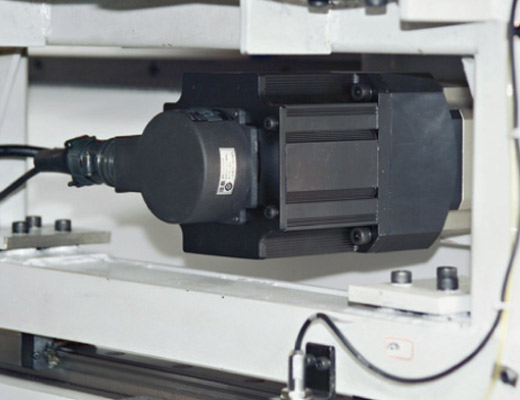

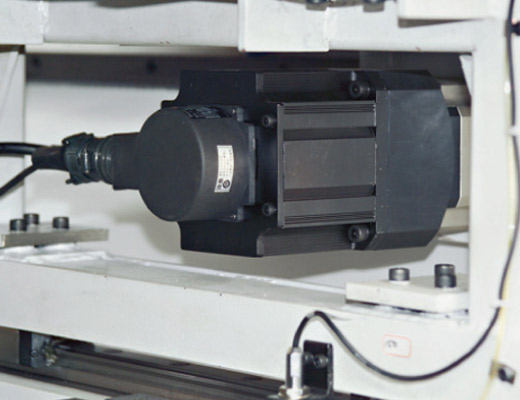

Left Shaping Mechanism- The feed system on the right and left finger shaper is driven by servo motor, providing high speed feed and increased efficiency.

- The table on the right and left finger shaper moves on precision linear gride ways for extra smooth movement.

- The feed system on the right and left finger shaper is driven by servo motor, providing high speed feed and increased efficiency.

-

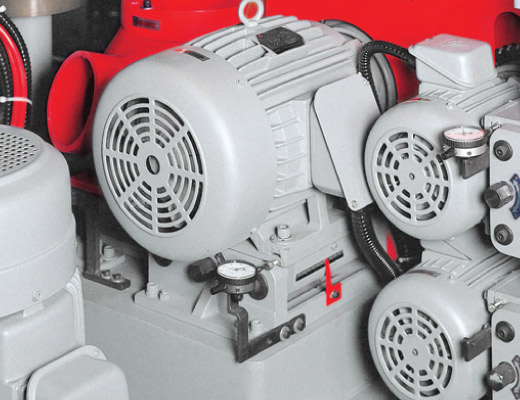

Servo Motor DriveThe trimming and scoring sawblade position are adjusted on the precision rod guides, which are hard chrome plated for maximum wear resistance. Micrometers are also provided for accurate indication for adjustment, ensuring superior jointing quality.

Servo Motor DriveThe trimming and scoring sawblade position are adjusted on the precision rod guides, which are hard chrome plated for maximum wear resistance. Micrometers are also provided for accurate indication for adjustment, ensuring superior jointing quality. -

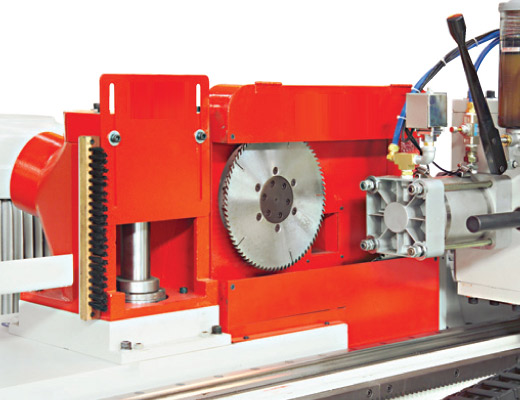

Cutter PresetterThe mechanism performs scoring, trimming, shaping operations on right end of the workpiece. Scoring blade in front of trimming blade cuts bottom edge to give tearing-free finish. Finger cutters produce smooth finger shape, cutting capacity 6 1/4″ thick.

Cutter PresetterThe mechanism performs scoring, trimming, shaping operations on right end of the workpiece. Scoring blade in front of trimming blade cuts bottom edge to give tearing-free finish. Finger cutters produce smooth finger shape, cutting capacity 6 1/4″ thick.

F-C06Finger Shaper (left End)It combines three functions – scoring, trimming, shaping in a unit on right end of the workpiece.

F-C06Finger Shaper (left End)It combines three functions – scoring, trimming, shaping in a unit on right end of the workpiece.

Production Rate- 2-4 cycles/min. (Long wood)

- 4-6 cycles/min. (Short wood)

- 2-4 cycles/min. (Long wood)

-

Left Shaping MechanismThe mechanism performs scoring, trimming, shaping and gluing operation on left end of the workpiece. Scoring blades cut top and bottom edges to prevent fear-out.

Left Shaping MechanismThe mechanism performs scoring, trimming, shaping and gluing operation on left end of the workpiece. Scoring blades cut top and bottom edges to prevent fear-out. -

Servo Motor Drive

Servo Motor Drive- The feed system on the right and left finger shaper is driven by servo motor, providing high speed feed and increased efficiency.

- The table on the right and left finger shaper moves on precision linear gride ways for extra smooth movement.

- The feed system on the right and left finger shaper is driven by servo motor, providing high speed feed and increased efficiency.

-

Cutter PresetterA cutter presetter is built on the right shaper for convenient cutter assembly.

Cutter PresetterA cutter presetter is built on the right shaper for convenient cutter assembly.

FA-03Assemble Press

FA-03Assemble Press- The assemble press employs two hydraulic cylinder at front and rear, providing more powerful and faster jointing performance. This special design also assure extremely consistent jointing effect on the entire wood.

- The assemble press joints short stock to produce long board length up to 6800mm.

A synchronized 2-step process allows the back of the press to continue jointing and cutting to length while the front of the press is performing pressing and outfeed motions.

- Times of cut are controlled by limit switches, which permits for maximum 4 times of cut setting.

- The assemble press employs two hydraulic cylinder at front and rear, providing more powerful and faster jointing performance. This special design also assure extremely consistent jointing effect on the entire wood.

F-T03Chain Type Pre-press Assemble Stand (less Infeed Conveyor Table)

F-T03Chain Type Pre-press Assemble Stand (less Infeed Conveyor Table)- The pre-press assemble stand employs chain feed, and provides 3 and 6 meters of length to choose from.

- This assemble stand provides prepressed board ready to be cut to length, and ensures accurate vertical and horizontal alignment of finger joint. The pre-press is fully synchronized with cut to length process.

- The pre-press assemble stand employs chain feed, and provides 3 and 6 meters of length to choose from.

Specification

Dimensions

FC-05

Finger Shaper (right End)

Finger Shaper (right End)

F-C06

Finger Shaper (left End)

Finger Shaper (left End)

FA-03

Assemble Press

Assemble Press

F-T03

Chain Type Pre-press Assemble Stand (less Infeed Conveyor Table)

Chain Type Pre-press Assemble Stand (less Infeed Conveyor Table)

About Us

As time passes, business becomes more and more competitive. Success lies in the ability to produce quality goods at competitive prices. OAV Equipment & Tools Inc. is constantly working hard to improve and strengthen its corporate structure and meet new challenges.

Since its establishment in 1980, the top priority of OAV has been to provide the highest level of customer satisfaction possible. OAV continues this process today with state of the art facilities, a diversified product range, and the most rigorous quality control process in the industry. At the same time, there is more to OAV than high manufacturing standards. It is our dedicated staff that sets us apart, each of them bringing their passion and unique talents to the company.

At OAV, our focus is not only to improve product quality, but to also make strides in research and development, customer service, and sales. Our greatest strength is our dedication to offering the best possible service to meet the needs of customers all over the world. We spare no effort to ensure that each of our customers receives the highest possible level of customer satisfaction.

The people of OAV are devoted to the pursuit of excellence in all stages of the manufacturing process, as well as post-sale services. We strive to make our sales team easy to work with for every customer, regardless of language barriers or cultural differences. Our sales representatives regularly undergo training in order to meet any challenges that may present themselves while working with customers from all over the world. We pride ourselves in continuously improving all aspects of our business structure in order to keep pace with, and eventually set, international standards.

Business Type: Exporter

Main Products

Edge Banding Machine, Sliding Table Saw, Panel Saw, Circular Saw, Wood Band Saw, Dust Collector, Cut Off Saw, Fully Auto Finger Jointi,CNC Machine , Disc Sander, Disc and Belt Sander, Wide Belt Sander, Meat & Bone Saw, Combination Machine, Boring Machine

Contact Details

Related Products

Economic Fully Auto Finger Jointing Line

Inquire Now

Other buyers also viewed these products

Cut Off Saw

Inquire Now

Heavy-Duty Auto Copy Shaping Machine

Inquire Now

Single Sided Cutting Boring Moulding Machine

Inquire Now

DOUBLE SPINDLE SHAPER 2070 SERIES

Inquire Now

Beam Saw

Inquire Now

Dust Collector

Inquire Now

INTERNAL AUTOMATIC COPY SHAPER

Inquire Now

All Categories

All Categories